Forté Technical Tips – The Low Speed Pre Ignition (LSPI) phenomenon

Turbocharged, direct-injected (DI) gasoline engines are rapidly growing in use. Their design provides improved fuel efficiency, lower emissions and increased power and performance. In particular, significant efficiency benefits can be achieved when a smaller, turbocharged DI engine is used to replace a larger, conventional engine of the same power.

The higher power density of these engines makes them prone to a phenomenon called low speed pre-ignition (LSPI). LSPI is an abnormal combustion event in which the fuel-air mixture ignites before intended, causing excessive pressures inside the engine’s cylinders. This can cause engine noise in mild cases, but when severe enough, LSPI can cause engine damage.

THE EMERGENCE OF THE LSPI PHENOMENON

While these engines provide higher power density and improved efficiency, they are also prone to LSPI. Manufacturers (OEMs) can adjust the operating conditions in the engines to address this problem, but this can reduce the engine’s efficiency. In fact, LSPI tends to become more prominent in the operating regime that is most beneficial to attaining improved fuel economy.

A growing body of knowledge demonstrates how hardware design, fuel composition and lubricant composition can impact LSPI. Unlike conventional knock, an LSPI event cannot be predicted and corrected by adjusting spark timing. As such, mitigating pre-ignition involves altering the design of the engine or lubricant to help avoid this emerging issue.

Low-speed pre-ignition (LSPI) is a premature combustion event occurring before spark ignition in turbocharged, downsized gasoline vehicles. As the name implies, it occurs when engines operate at low speeds and high loads. It can result in extremely high cylinder-pressures and can lead to heavy knock. At a minimum, LSPI can generate an audible knocking noise noticeable to the driver. Repeated exposure to these conditions can cause engine hardware failure, including broken spark plugs and cracked pistons. A characteristic of LSPI is that one event often leads to subsequent events. The events will frequently occur in an alternating pattern between pre-ignition and regular combustion.

When driving the management system will retard the ignition timing when a knock is detected. This can in turn reduce vehicle performance and response and an audible noise will not always be heard by the driver.

Several theories exist to explain the mechanism of LSPI. One theory is that an oil droplet enters the combustion chamber from a crevice between the piston and cylinder wall. Another theory is that when the pressure in the crankcase increases from incomplete combustion due to contaminated injectors, the pressure increase can cause oil to bypass the valve stem oil seal and drop onto the valve. The oil droplet mixes with fuel and auto-ignites on compression in this mechanism.

Sometimes, this can be identified with a borescope camera through the spark plug hole. There may be a polish mark on the top of the piston where the oil is igniting. Prolonged ignition at the same spot can result in piston damage.

DIRECT INJECTION

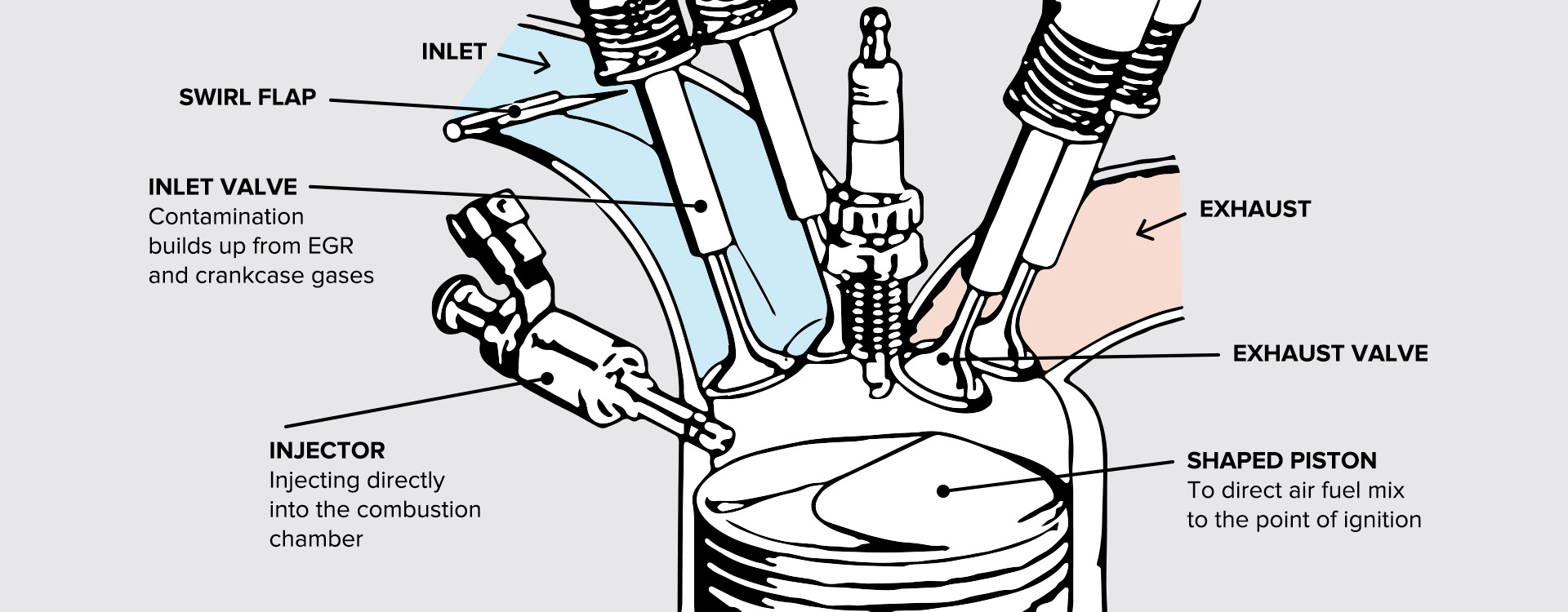

Direct injection engines can suffer from valve stick due to no fuel or treatment wash across the inlet valves. As contamination from the crankcase and EGR system increases, the operation of the valves is affected.

Many factors have been demonstrated to impact low speed pre-ignition (LSPI), including engine designs, fuel composition and lubricant composition. The detergent chemistry has the most noticeable impact on the lubricant side. Oils with higher concentrations of calcium, found in many detergent systems, have been shown to increase the frequency of LSPI. The exact chemistry of the detergent is less important to LSPI than the calcium content. Ignition point of the oil is vital and raising the ignition point reduces the possibility of ignition on compression.

SOLUTION

Keeping the fuel injectors and the combustion chamber clean promotes complete combustion and reduces the impact of increased pressure during incomplete combustion events. A clean system maintains the cylinder pressure as high pressure and temperature are key to LSPI.

Our products can reduce the risk of LSPI phenomenon by keeping systems pristine:

- Advanced Formula Motor Flush

- Advanced Formula Petrol Treatment

- Petrol Specialist Injector Cleaner

- Air Intake & Valve Cleaner