Forté Technical Tips – Sludge from glycerin-based coolants

COOLANT FLUID

Vehicles are designed to be driven in different climates, so whatever fluid is used to cool the engine, it must have:

- A very low freezing point

- A high boiling point (120 – 135°C) and the capacity to hold a lot of heat.

To reach those goals, most coolant is formulated using ethylene glycol, but others, like G13, use glycerine instead.

GLYCERIN-BASED COOLANT

A benefit of glycerin is that it’s environmentally more sustainable than ethylene glycol. It decreases CO2 emissions and extends the life of coolants. However, glycerine is less stable to anti-corrosive additives because of how corrosive glycerine is itself. This causes:

- Degradation of coolant

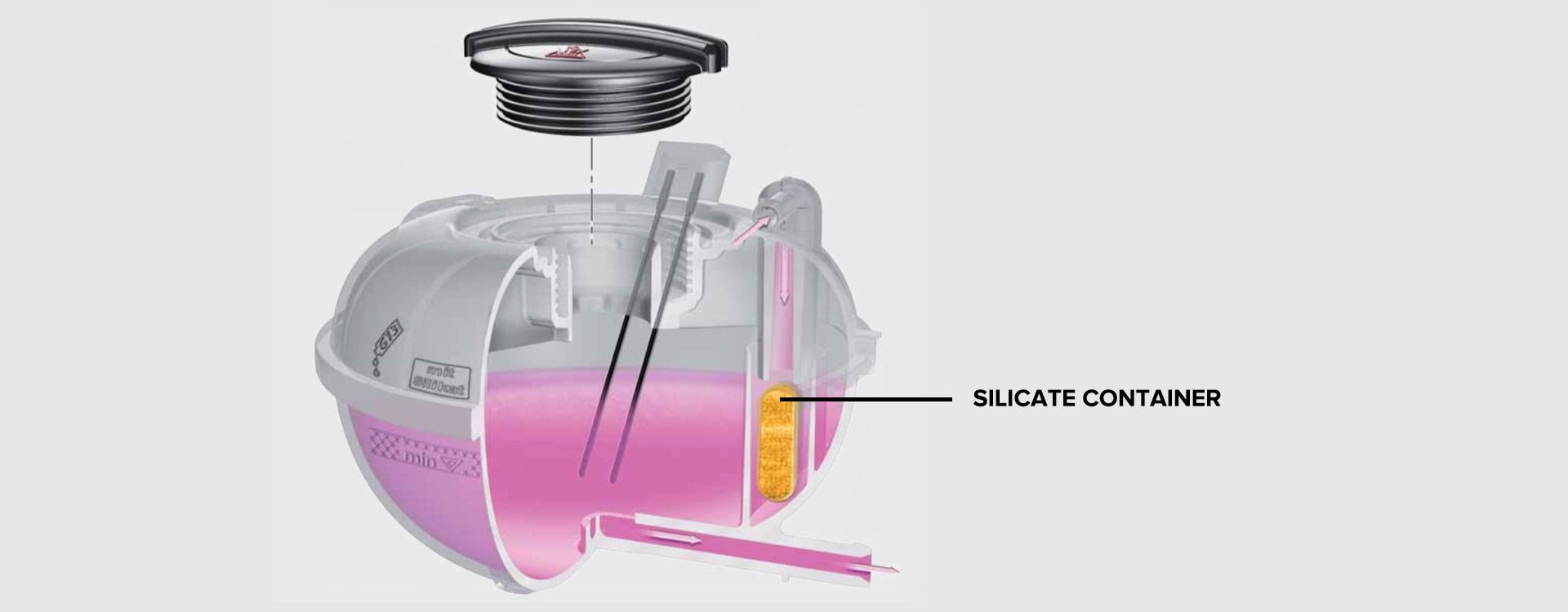

- Build-up of silicate sediments or deposits in the system

- Corrosion of the internal cooling system surfaces

- Reduction in heat transfer properties of the fluid, causing increased fuel consumption, increased emissions, component failure and poor heater performance.

DIAGNOSING THE ISSUES

- Driver reports insufficient or irregular heat output

- Discolouration of the coolant in the header tank

SOLUTION

Replacing the coolant or changing coolant technology is not enough. Sludge and deposits will remain in the cooling system and contaminate the new coolant instantly. It is therefore required to flush the cooling system using a Forté Bio Degreaser & Cooling System Flush, as it is a heavy-duty cleaner/degreaser free of petroleum or chlorinated solvents.

It effectively removes oil, sludge, scale and rust deposits from the internal surfaces of automotive cooling systems. It keeps contamination in suspension whilst cleaning and is safe for all cooling system components.

PROCEDURE

FLUSH THE COOLING SYSTEM

- Add 2 bottles of Forté Bio Degreaser & Cooling System Flush to the cooling system

- Ensure heater position is set to ‘hot’

- Run vehicle to operating temperature

- Run vehicle at 1200 – 1500 rpm for up to 1 hour

- If the heater output is insufficient, carry out a 50-mile drive cycle or until there is sufficient heater output inside the vehicle

- Allow engine to cool

- Drain cooling system and rinse with water

REFILL WITH NEW COOLANT

When the cooling system has been rinsed, refill with coolant meeting the manufacturers specification.

PROTECT THE SYSTEM

The cooling system has been affected by the corrosion of the coolant on the internal surfaces and may suffer from leaks. It is recommended to add Forté Radiator Stop Leak & Cooling System Conditioner to reinforce the protection.

Find out more at: www.forteuk.co.uk