Forté Technical Tips – How does a particulate matter sensor work?

Want to better understand how a particulate matter sensor works? Join us as we take a look at what a particulate matter sensor is, how they can fail, how they work, and the Forté solution that restores and maintains vehicle performance for improved customer satisfaction.

What is a particulate matter sensor?

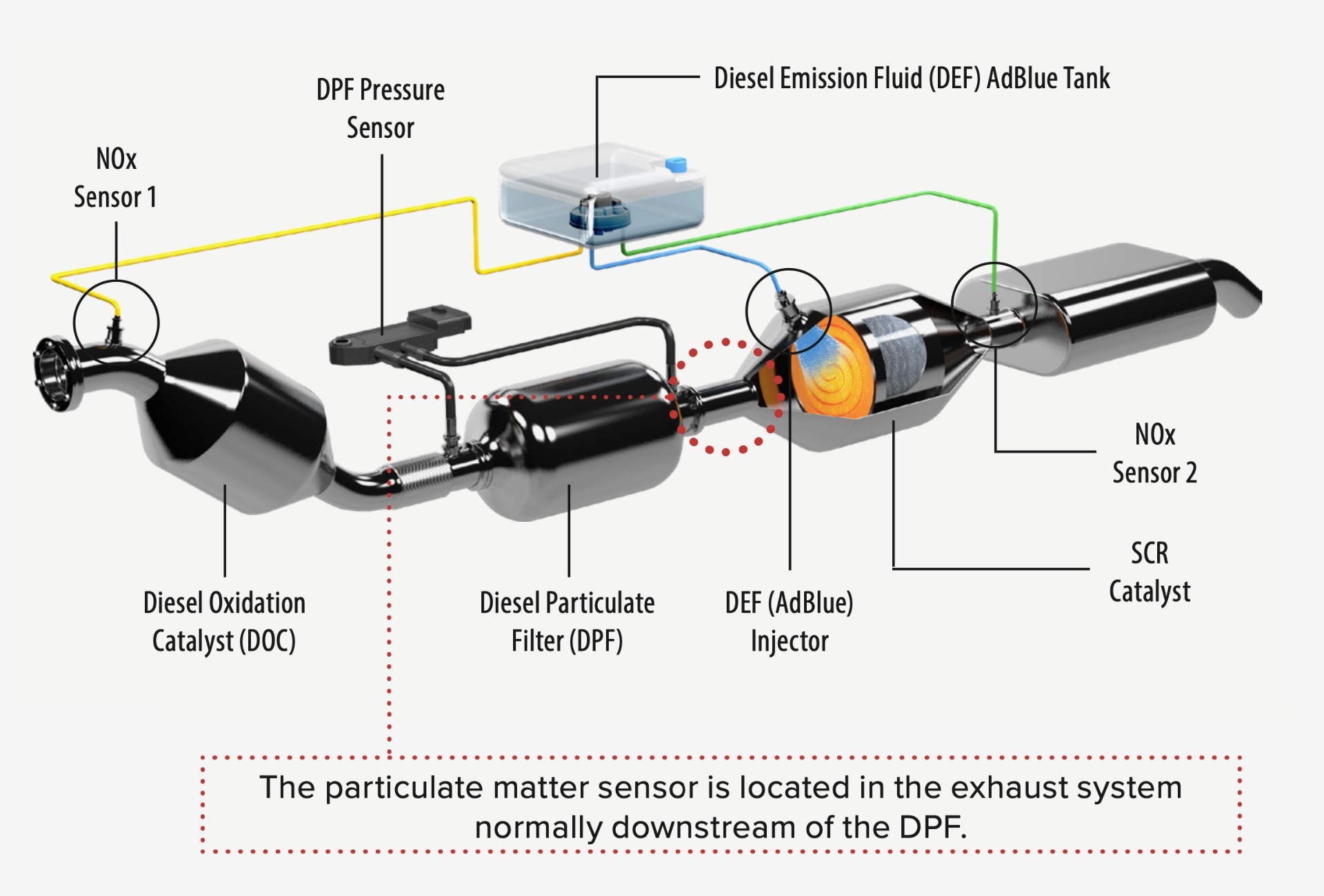

Particulate matter sensors have been developed for all modern diesel vehicles to estimate the amount of soot in a diesel particulate filter. These sensors are fitted upstream of the exhaust system to detect excessive PM emissions.

What does a particulate matter sensor do?

In simple terms, particulate matter sensors control and diagnose emission systems, and accurately utilise DPF regeneration strategies. This helps to estimate soot amounts in the DPF, and triggers an OBD fault signal by detecting DPF failure resulting in excess PM emissions.

How does a particulate matter sensor work?

When it comes to understanding how does a particulate matter sensor works, the process is simple and effective.

- The soot particle sensing element consists of two interdigital comb-like electrodes (IDE) with an initial infinite electrical resistance, an internal heater and a positive temperature coefficient resistor for temperature measurement. PM sensor function is based on resistance measurements during sensor operation.

- Soot particles are deposited on an electrode structure, forming conductive soot trails between the electrodes. When the sensor reaches a certain conductivity threshold, it notifies the engine system that the DPF needs to complete a regeneration process and burn the particulates.

- Before each measurement phase, the sensor element is regenerated through heating so that the sensor element adopts a defined status before the start of the next measurement.

- PM sensors usually work with the NOx sensor, which measures the NOx (Nitrogen Oxide) content to control the emissions exiting the vehicle’s exhaust tailpipe.

What can cause a particulate matter sensor to fail?

Now you know how a particulate matter sensor works and what it is, you can start to understand key areas that can cause it to fail. The sensor is usually prone to failing when the soot loading of the DPF (Diesel Particulate Filter) is too high, which causes regeneration to stop. This leads to excessive soot accumulation, which clogs the diesel particulate filter and can cause the PM sensor to fail.

If this is the case, instant cleaning of the DPF is advisable and error codes related to the PM sensor may be recorded. Incorrect readings, a faulty PM sensor unit, a damaged or flooded sensor, or a short or open circuit could cause this.

How can I fix a particulate matter sensor temperature circuit fault code?

Cleaning the sensor and the diesel particulate sensor could cure the system fault; however, if the fault remains, we recommend getting the sensor and operating system checked.

Handy note: PM sensors consist of a probe and module and cannot be replaced separately; therefore, they must be replaced as a unit.

Forté Advanced Formula Diesel Treatment

As the sensor monitors the function of the diesel particle filter (DPF), it also helps to reduce particulate emissions by up to 99%, so it’s important to ensure it’s all in order. That’s where our innovative product can be used. Regularly keeping the fuel system clean will reduce soot content in the exhaust gas, prolong the sensor operation, and prevent clogging of the DPF.

Forté Advanced Formula Diesel Treatment helps to…

- Clean and lubricates the entire fuel system

- Lubricates and extend the life of injectors and fuel pump

- Improves engine performance, drivability & cold starts

- Increases the diesel lubricity up to 46%

- Reduces black smoke emissions

…and much more.

When it comes to understanding how a particulate matter sensor works, our specialist knowledge and products can help reduce failures and emissions, improve overall engine performance, and maximise drivability. For more information on this topic, contact us.