Forté Technical Tips – Diesel fuel contamination and modern diesel fuels

Want to improve your knowledge on modern diesel fuels and diesel fuel contamination? Join us as we take a look at the different types of biodiesel, e-fuels and how to reduce the risk of contaminating diesel fuel once and for all with the help of our innovative products.

What are the different types of biodiesel?

FAME (fatty acid methyl ester) – This is produced from vegetable oils, animal fats or waste cooking oils by transesterification, where various oils (triglycerides) are converted to methyl esters. This is the most widely available type of biodiesel.

HVO (hydrotreated vegetable oil) – This is the product of fats or vegetable oils – alone or blended with petroleum. Diesel produced using this process is often called renewable diesel to differentiate it from FAME biodiesel. The overall production process is typically more costly than for FAME, however HVO is a drop-in fuel which can be directly used in existing diesel engines without any further modification.

GTL (gas to liquid) – This type of biodiesel consists of C13-C18 paraffins obtained by Fischer-Tropsch reactions between CO and H2 (gas synthesis) products for biomass gasification.

DME (dimethyl ether) – This is obtained from synthesised methanol, like the GTL, starting from the synthesis gas obtained from biomass.

BTL (biomass to liquid fuels) – This is a synthetic fuel produced from biomass by means of thermo-chemical conversion. The end product can be fuels that are chemically different from conventional fuels such as gasoline or diesel but can also be used in diesel engines.

What are e-fuels?

E-fuels are produced with the help of electricity from renewable energy sources, water and CO2 from the air. In contrast to conventional fuels, they do not release additional CO2 but are climate neutral in the entire balance. This helps to drastically reduce the harmful emissions associated with combustion engines, and e-fuels play a key role in decarbonisation strategies. However, they are very expensive and not readily available.

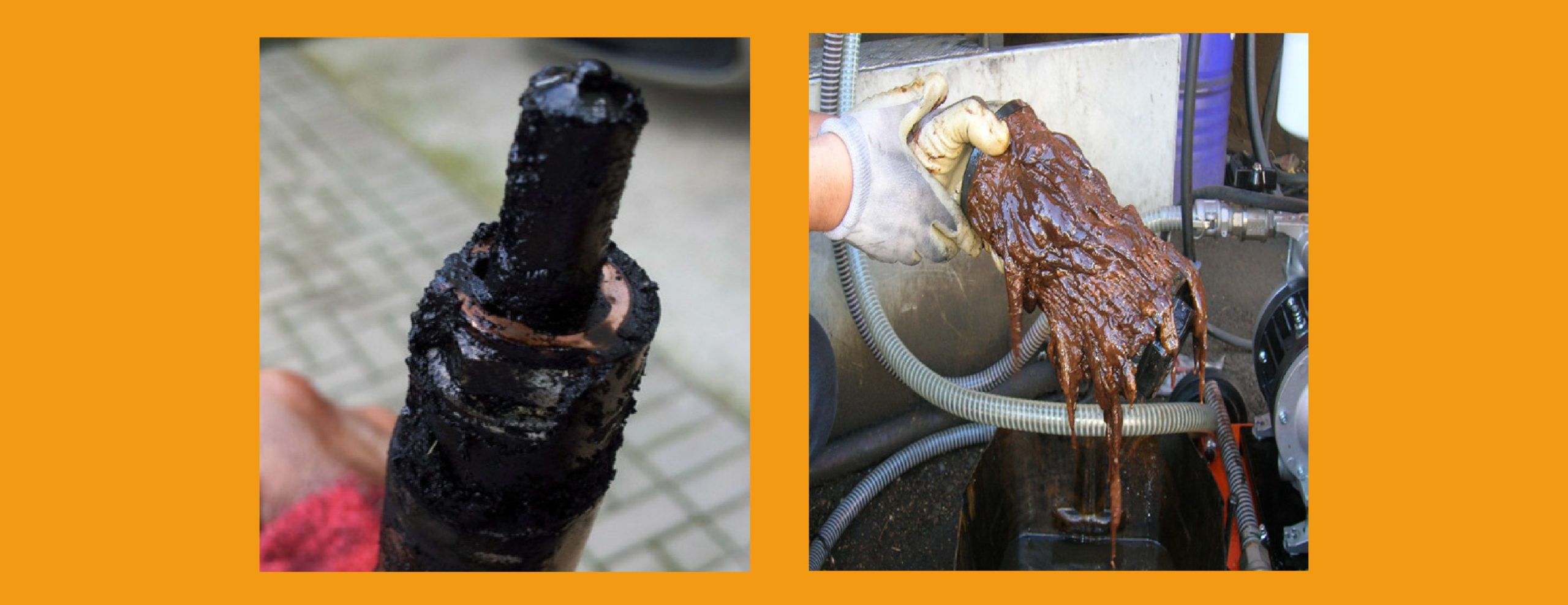

How and why does diesel fuel contamination happen?

Put simply, modern fuel systems of diesel engines can create pressures between 1250 to well over 2000 bar. With the increase of bio content in modern fuels, biofuel’s hygroscopic nature absorbs moisture, which can be a breeding ground for the growth of bacteria and fungi. This causes diesel fuel contamination, which enters the fuel tank, leading to blockages, faults and ultimately vehicle breakdowns.

What is the solution to diesel fuel contamination?

In order to reduce the risk of diesel fuel contamination, we recommend using Forté Diesel Treatment to clean the fuel system at regular intervals and maintain fuel system cleanliness, efficiency and restore fuel injector spray patterns and operation.

Regularly treating bulk fuel tanks will ensure all vehicles filling from that tank, will receive the benefits of cleaning the fuel system. Treatment within the bulk tank will prevent the growth of bacteria and fungi.

Our innovative solution helps to…

- Reduce the possibility of particle ingress to the fuel pump and injectors

- Provide vital additional lubrication to the system during the priming process- up to 46%

- Provide an effective and quick clean-up of the fuel system components, maximising fuel economy

…and much more.

Ensuring that you put in place the right preventative solutions to avoid diesel fuel contamination is essential when it comes to looking after vehicles, and improving customer satisfaction. For more on this topic, or if you have a query about our products, please get in touch with us.